Motivation

This is my second take on the Trapezoid VCO designed by Don Tillman. My first implementation can be found here. This time I mounted the PCB's parallel to the front to save space and integrated the wave shapers. The core is still based on the original design from Don (used with permission). I found the original article and schematic about the Trapezoid VCO on Don Tillman's site (Link to original article from 19 July 2003). The article consists off three parts with the core implementation in part 2. I kept the basic idea and changed nearly everything else. I use an other exponentiator scheme and temperature stabilization. Another reference voltage device is used. And quadrature square outputs are implemented. As well as the additional waveforms triangle, sine, ramp up, ramp down and pulse.

Specs and features

- Trapezoid quadrature output

- Square quadrature output

- Triangle quadrature output

- Sine quadrature output

- Pulse output, 0deg, 90deg

- Ramp up output 0deg, 90deg

- Ramp down output 0deg, 90deg

- Through zero modulation

- PWM input

- V/Oct, FM log and trough zero CV input

- Temperature compensated

- Coarse and fine frequency setting

- Runs on +/-15V and +/-12V

- Power consumption around 135mA each rail

Implementation

Schematic

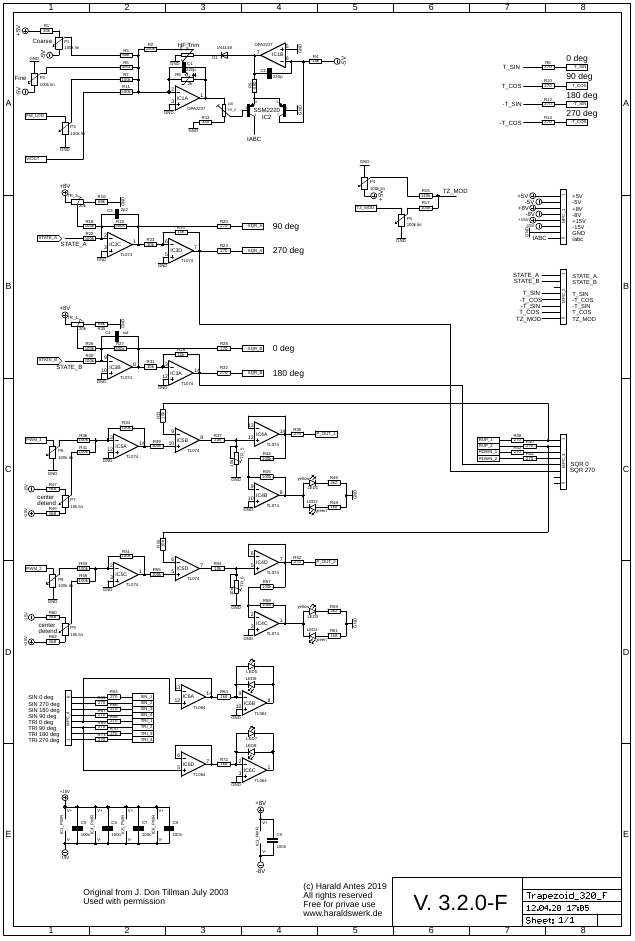

Trapezoid VCO schematic: Control board

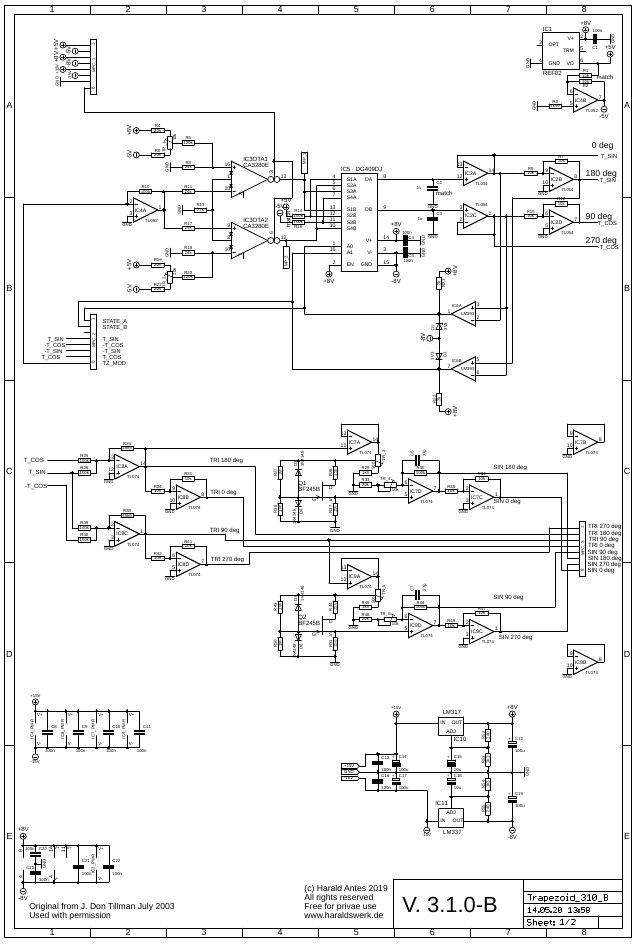

Trapezoid VCO schematic: Main board

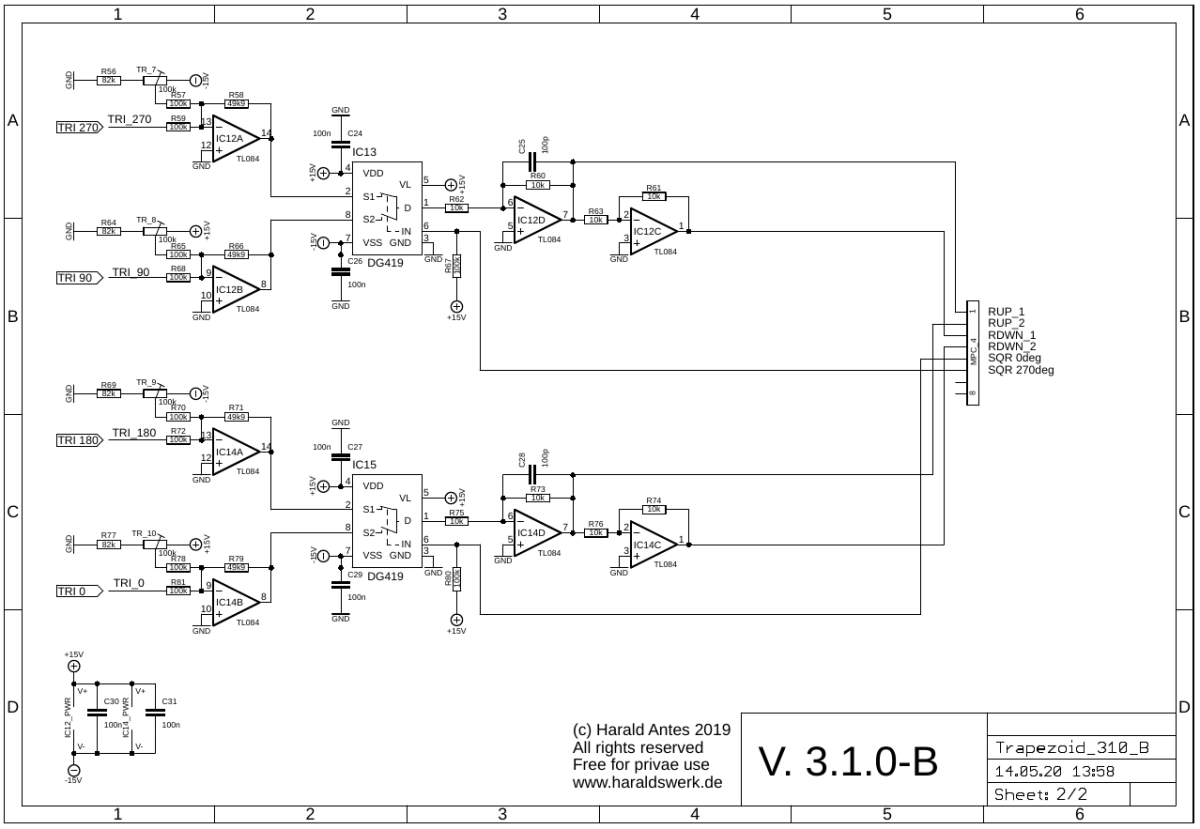

Trapezoid VCO schematic: Main board

Description:

J. Donald Tillman did an excellent job describing the core of his Trapezoid VCO. Please refer to the original article as linked above. Don Tillman gave me the advice to use only two capacitors in the core. The exponentiator I use is a well known and a classical design. You can find many description of it out there. The rest is straight forward.

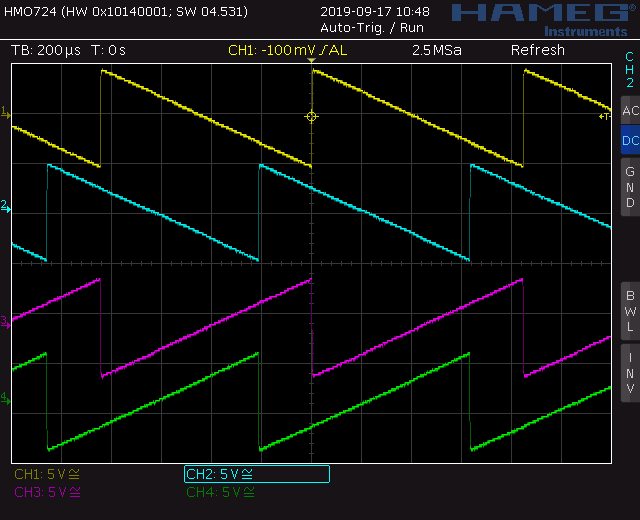

Trapezoid VCO screenshot: Trapezoid quadrature waveforms

Trapezoid VCO screenshot: Square quadrature waveforms

Trapezoid VCO screenshot: Saw waveforms

Trapezoid VCO screenshot: Triangle quadrature waveforms

Trapezoid VCO screenshot: Sine quadrature waveforms

Trapezoid VCO screenshot: Pulse waveforms

Trapezoid VCO screenshot: Through zero modulation

Trapezoid VCO screenshot: Through zero modulation

Trapezoid VCO screenshot: Through zero modulation

Top

Calibration

- First make a gross test. You should have a signal at every output, the LED lit, pots and inputs reacting.

- OTA offset voltage

- Remove DG409

- Ground the V/Oct input

- Set P4 (TZ) to max.

- Set P1 (coarse frequency) slightly below 12:00.

- Set P2 (fine frequency) to center.

- Set P3 (FM log) to zero

- Set P5 (TZ mod) to zero

- Measure the DC offset at pin 13 of the OTA (MP_1 on the backside). Adjust trimmer TR1 (main PCB) to zero.

- Measure the DC offset at pin 12 of the OTA (MP_2 on the backside). Adjust trimmer TR2 (main PCB) to zero.

- V/Oct adjust

- Low frequency: Set the frequency to about 100Hz

- Apply +1V to the V/OCT input (Use Scaled Voltage Reference or keyboard). The frequency should double

- Adjust Trimmer TR_2 (control PCB) to until it works.

- High frequency: Set the frequency to about 2500Hz

- Apply +1V to the V/OCT input (Use precision voltage source or keyboard). The frequency should double

- Adjust Trimmer TR_1 (control PCB) to until it works.

- Repeat low and high frequency trim.

- A more elaborate procedure is found here: NGF: VCO Core two

- Sine adjust

- TR_1 (TR_3) adjusts the amplitude, TR_2 (TR_4) adjusts the waveform

- Start with TR_1 (TR_3) and then adjust TR_2 (TR_4).

- Those adjustments are not independent. Go back and forth until you are satisfied.

- Ramp adjust

- Adjust TR_7 (TR_9) and TR_8 (TR_10) (main PCB) until the ramp looks like a straight line

- Square offset

- Adjust TR_3 (TR_4) (control PCB) for zero offset.

- Pulse output level

- Adjust TR_5 (TR_6) (control PCB) for the desired output level (5Vpp).

Building hints

- R7 (2k tempco 3300ppm) is mounted beneath the SSM2220

- Match C2 and C2 (Main PCB

Special parts

- The SSM2220 could be replaced with two (hand matched) transistors

- The OTA CA3280 could be replaced with the AS3280 (not tested though).

Download

Trapezoid VCO flat main board documentation downloadTrapezoid VCO flat main board Gerber files download

Trapezoid VCO flat control board documentation download

Trapezoid VCO flat control board Gerber files download